Carbon Chain Energy Renewable Fuels

Overview

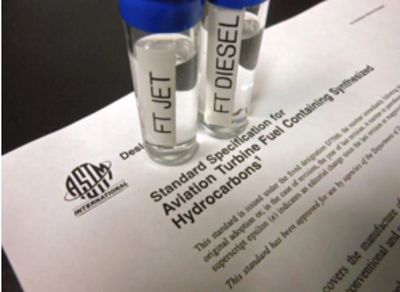

Carbon Chain Energy Renewable Fuels, (“CCERF”), to be developed by Carbon Chain Energy, will be among the first wave of second generation commercial scale, cellulosic renewable fuel refineries in the U.S. The technology consists of a proven and certified, patented state-of-the-art, commercial scale, near zero emission carbon based “green wood waste” biomass gasifier. The technology also has a highly efficient back-end patented, gas-to-liquid (“GTL”) conversion system that generates a zero sulfur, drop-in premium ASTM D975 diesel fuel and/or jet fuel at a production cost that is below petroleum diesel and biodiesel fuels. Presently in 2017, cellulosic and advanced biofuels production in the U.S. has been well below the EPA’s RFS2 statutory annual mandates.

The Carbon Chain Energy Renewable Fuel Advantage

CCERF will efficiently convert green wood waste diverted from landfills, as well as other types of wood waste from forestry maintenance, into premium #2 renewable diesel fuel and/or jet fuel. The Refinery’s use of certified and commercially proven technologies, coupled with using cellulosic feed stock diverted from landfills, solves several major environmental problems – overflowing landfills; environmentally damaging disposal and reduction techniques; the elimination of harmful emissions and inefficient synthetic fuel production techniques.

The Market

Transportation fuel is one of the top three energy use sectors in the United States, accounting for over two‐thirds or 14 million of the 20 million barrels of crude oil consumed daily in 2016. Of that, the United States imports over half from foreign sources according to the U.S. Energy Information Administration (EIA). In California, the transportation sector represents roughly half of all energy consumed and is more than 90 percent dependent on petroleum. Despite the current economic turmoil and volatile oil prices, Californians still consume more than 50 million combined gallons of gasoline and diesel each day, or 1.2 million barrels per day.

Product Performance

CCERF Renewable #2 diesel fuel produced from this combination of proven technologies has numerous advantages over petroleum diesel and first generation biofuels. Our fuel has similar energy content per weight and burns up to 90% cleaner than petroleum diesel. CCERF Renewable diesel fuel is also dramatically superior to current ethanol or Renewable diesel fuels in that it has superior characteristics and does not require blending with petroleum diesel. Industry experts such as Carbon Solutions Group in Chicago, Illinois claim this feature alone is a “game changer” because it eliminates the numerous limitations that have plagued the biofuels industry. The CCERF Renewable #2 diesel fuel is also an excellent “Blend Stock” due to its high Cetane content that can also enhance the petroleum diesel fuels being produced today.

Technology Validation

Carbon Chain Energy has identified and is currently in negotiations with two of the world’s leading companies in the field of biomass gasification, GTL conversion, and Engineering, Procurement, Construction services (“EPC”). The final selection of the both the gasification system, and the Fischer-Tropsch technology, along with all other required process units in the overall facility will be formalized with the selected EPC during the Front End Engineering phase, FEL 3.

Our Customers

One of the world's six "supermajor" oil and gas companies. Carbon Chain Energy is in the process of finalizing a Renewable Diesel Purchase Letter of Intent that includes two years for construction then an initial ten year term with the first product delivery at current market prices.

Green Fuel Initiatives and Opportunities

When it comes to the environment, aviation has a rather dirty reputation. The industry produced 689 million tons of CO2 in 2012, according to Air Transport Action Group (12% of global transportation's carbon dioxide emissions) -- a number that is sure to grow as global demand for flight continues to skyrocket. As a result the aviation industry is going green.

- Airlines: A “core group” of 16 airlines have agreed to buy alternative aviation fuel from two producers, according to the Air Transport Association of America. Air Canada, American Airlines, Atlas Air, Delta Air Lines, FedEx Express, JetBlue Airways, Lufthansa German Airlines, Mexicana Airlines, Polar Air Cargo, Southwest Airlines, United Airlines, UPS Airlines, US Airways, Seattle-based Alaska Airlines and Hawaiian Airlines.

- Aircraft Manufactures: Aircraft makers Airbus, US Boeing and Brazilian Embraer have agreed to jointly promote the development of affordable biofuels for the aviation industry. The three companies have signed an agreement aimed at promoting and speeding up the availability of green jet fuel sources through collaborations with governments, biofuel makers and other stakeholders. The move is in line with the aviation sector's plan to cut its environmental footprint. The industry is looking to have cut by 50% on 2005 levels its greenhouse gas emissions by 2050. 3.

- Department of Defense: In September 2014, the Department of Defense awarded $210 million under the Defense Production Act to Emerald Biofuels, Fulcrum BioEnergy and Red Rock Bio towards the construction of biorefineries that produce cost-competitive, drop-in military biofuels. Under the grants, the companies will build biorefineries to produce military spec fuel that is expected to cost the US military, on a weighted average, less than $3.50 per gallon — or cost competitive with petroleum-based fuels, with availability expected as soon as 2016, and have a 50 percent of greater reduction of emissions compared to conventional fuels. The biorefineries, once complete, will have a combined capacity for producing 100 million gallons of military-spec jet fuel and marine diesel.

Strategic Partnerships

Carbon Chain Energy has developed Strategic Alliances with recognized “Best in Class” industry experts and proven technology providers in the biomass to renewable fuels sector that mitigates much or all of the operating risk and creates value for the Project and its financial partners. Performance Insurance Wraps may be provided by top underwriters if required.

Value Proposition

Environmental:

- Approximately 384,000 wet tons per year of Green Wood Waste used as feedstock is diverted from landfills thus avoiding the creation of methane gas as it decomposes. Methane is 56 times more potent as a greenhouse gas than CO2 over a 20-year period. This project is expected to avoid an estimated 1.1 million MtCO2e from general landfill operations per year.

- The Renewable fuel that will be produced will be 90% cleaner than its petroleum based counterparts.

Economic: Federal, State and Local

- A single Refinery is projected to support 387 jobs and generate $22.3M in wages annually, contributing $2.4M in Federal taxes and $2.1M in Arizona taxes each year.

- Each job represents an average annual wage of $57,706.

- • A single Refinery that produces 19+ million gallons of renewable fuel per year is projected to represent 7% of Arizona’s 2014 renewable fuel sector.

Financial:

- The Refinery will require approximately $290 million invested capital to generate over 19 million gallons of cellulosic Renewable Diesel fuel annually with first year Sales, EBITDA and After Tax Cash Flow of $133 million, $103 million, and $54 million, respectively.

- 20 year Unlevered IRR of 36.47%